|

Yunyan Special Cement Building Materials Co., Ltd.

|

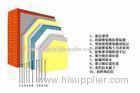

Thermal Insulation Mortar Exterior Insulation Finishing System for walls

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Thermal Insulation Mortar Exter

Thermal Insulation Mortar Exterior Insulation Finishing System for walls

Product features

It has low thermal conductivity and good thermal insulation property that can inhibit the difference in temperature of the wall between summer and winter season effectively.

It has good cohesive force and be suitable for different base planes.

It has low contraction efficiency that can prevent effectively the cracking and hollowing and avoid forming hot and cold bridge.

The construction is convenient and the product can be used after adding water and stirring.

It is fire-retardant, non-toxic, environmental and good weather resistance.

It if fast drying and drought, has good construction property.

Scope of application

It is suitable for the insulations of various internal and exterior walls and different household floors, basements and heating system, etc.

It is suitable for the play mode built-in that can make a protective layer for the EPS.XPS thermal insulation system.

Treatment of base plane

The base materials should be smooth, strong, clean, and dry and non-grease, concrete curing admixture and other loose materials.

Product usage

Depend on the thermal insulation thickness.

Construction technology

Mix thermal insulation glazed hollow bead mortar and water as mixing ratio of 25: (26-5) kg, string completely and standing for 5 minutes, then stir again to get better effect.

Plaster the mortar on the wall evenly, leveling with scraper; the thickness of mortar for each time should be about 2 centimeters, and interval is about 24hours.

The curing time of thermal insulation glazed hollow bead mortar should be more than 5 days, depending on the thickness and temperature.

The insulation layer should be covered by alkali resistant mash cloth and mortar overlay which should use the polymer mortar with good flexibility and excellent water resistance.

Attentions

It should be operated in 5 -40 environment.

The crust should be removed the surface of mortar becoming dry and strong.

Never mix the dried mortar with water to reuse.

Storage period

Keep in cold and dry place, unopened product is valid for 1 year.

Spec

25kg/bag